Greenheck Fan Supplier Trial And Commercial

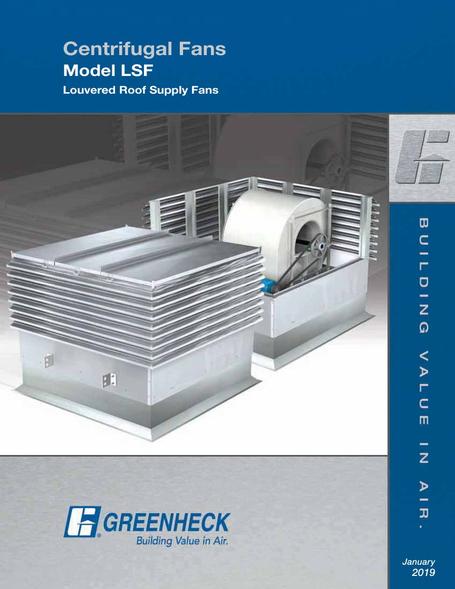

Colby Equipment Company represents manufacturers of industrial and commercial air handling equipment and is one of the largest suppliers of HVAC equipment in the Midwest. Most of the company’s manufacturing still takes place in Schofield additional manufacturing and assembly facilities are located in California, Kentucky, North Carolina, China, Mexico, and Delhi NCR Region, India. Today, Greenheck brand fans, energy-recovery ventilators, packaged ventilation, make-up air units, dampers, louvers, commercial kitchen ventilation, laboratory exhaust systems, and coils are shipped around the globe. Theyre commonly used to reduce moisture and remove smoke and odors in.Greenheck began business in 1947 as a tiny sheet metal shop in Schofield, Wisconsin. Greenheck equipment is used in all types of commercial, institutional, and industrial buildings in applications from comfort ventilation to manufacturing processes.Greenheck is known worldwide as the leading manufacturer of air-movement and control equipment.

No other company offers a wider selection of these products. The company has sales in excess of $300 million annually, employs more than 2,000 and has over a million square feet of manufacturing space. No matter how you measure it, Greenheck is number one in air movement and control.Most manufacturing takes place in Schofield, a small city adjacent to the northern Wisconsin business hub of Wausau. The company also has two other damper/louver manufacturing facilities in Frankfort, KY. And Sacramento, Calif.Greenheck products are usually hidden behind the walls or on the roofs of office buildings, hotels, shopping malls, restaurants, schools, industrial plants and other commercial buildings.

Images providedEditor’s Note: This article is Part I of a two-part article. It installed a SEYI servo press system. Air movement equipment manufacturer Greenheck needed to expand its stamping capacity, accelerate production, and counter forming problems like springback.

Capacity Expansion Needed to Meet Product DemandThe manufacturer needed to bump up its stamping capacity rapidly to meet growing product demand.Growing Pains. One of its recent operational innovations was installing a new servo press system. “Most of our work is hidden in ceilings and duct works,” said Manufacturing Engineer Tom Franke.Like its products, much of Greenheck’s innovation is unseen because it occurs in its operations. By 6 ft.Ironically, considering the omnipresence of its products, they are rarely visible. Its smallest fan is 12 by 12 by 4 in., commonly used in hotel restrooms its largest is a lab exhaust fan at 12 ft. Greenheck’s comprehensive line of ventilation equipment includes fans, dampers, louvers, kitchen ventilation hoods, energy recovery, makeup air units, indoor air handling units, dedicated outdoor air systems, energy recovery ventilators, duct heaters, HVAC coils, airflow measurement, motor starters, fan monitoring systems, and centrifugal and vane axial fans.

Greenheck Fan Supplier Upgrade Its Stamping

One 125-ton mechanical press, in particular, was ready for a rebuild.“We figured if we’re moving it over, we might as well rebuild it or replace it,” Franke said. To add capacity, opening the opportunity to move the stamping department into its own building and to upgrade its stamping operations.Some of the company’s presses were aging. A number of buildings were added throughout the U.S.

Meeting tolerances is not only a function of fan performance, but is even more critical for downstream operations, such as welding. “Obviously, using two operations to make a part is not as cost-effective as using one,” Franke said.Downstream Operations. In the past, how the company combated springback was to blank out the parts on a mechanical press and then hand-feed them to a hydraulic press, using the programmable action to lower the ram slowly to stress-relieve that material tension to form those parts. “You always have to deal with that with those materials.“Two Operations to One. The blades are stamped from a range of materials—5052 aluminum, 3000 aluminum, hot-rolled steel, cold-rolled and galvanized steel, and stainless steel.All of them have some kind of springback tension in them, Franke said. It’s pretty imperative that we can stamp parts to meet tolerance.”Materials.

Also, the controller was adaptable so that the communication with auxiliary equipment required could occur,” he explained. The flexibility of the programmable servo press allowed Greenheck to optimize stroke length and press speed for each die scheduled to run through this cell.“SEYI’s standard control functions allowed quick setup of press perimeters. They also evaluated the bed size.The new servo press helped increase productivity and throughput by more than 15% right away because the operators could take advantage of servo modes like pendulum.“Once we spec’d the press, we reached out to our machine vendors, acquiring quotes, and trying to get an apples-to-apples comparison so we could make a good judgment.”Greenheck replaced the older 125-ton mechanical press in February 2019 with a new SEYI SD1-220 servo press system with fully automated material handling.The SD1 220 servo press was selected primarily based on tooling dimensions, die tonnage, and maximum stroke length requirements, according to Rick Wenzel of BDC Machinery, the integrator that coordinated the press system installation. They determined that they could put additional volume on a new servo press. He and his team did some benchmarking, visited different facilities that had servo presses, and talked with operators and production management there to see what they experienced with them.“We saw the value of a servo press and the innovation it could bring to our business,” Franke said.One of the first actions they took was to try to match existing tooling with the press, based on volumes.

“That way we can stress-relieve the part before the ram comes back up. One profile they’re using is the ability to hold at bottom dead center. Two of the modes help them counter springback problems, and the other helps speed up throughput.Hold at BDC.

It was designed with a focus on quick changeover—not only of the die but the entire coil feed and material handling—so that Greenheck could produce small part batches and implement lean manufacturing. They’ve wanted to dive into the machine to see what they can do with it ‘How can I make it run faster?’” Press Installation Includes Automated Material HandlingThe press system’s performance goes beyond the press’s features and capabilities. The majority of our operators have been incredibly excited. The operator morale has increased with the new technology.

0 kommentar(er)

0 kommentar(er)